About

Est. 2014 in Arizona, Foye began as a lightbulb moment. Its founders are from manufacturing and engineering backgrounds, and were hearing from OEM's that they had to get their metal components from China but they:

Couldn't get past the language barrier

Couldn't get parts to arrive to a reliable schedule

Couldn't trust the quality of incoming parts

Couldn't build a manufacturing model around Asian-sourced raw goods.

And thus, Foye was born, a USA-based LLC, with language & cross cultural communication skills, manufacturing & quality control experience, and a knack for trans-continental logistics. In three short years, Foye grew into a trusted and valued sourcing partner for some of the biggest names in lighting, kiosk, and machinery industries. Now based in Colorado with a storage facility, Foye has grown into a Just-In-Time fulfillment partner, holding inventory for clients off their books until they’re needed, to help lower effective lead times and inventory turnover ratios.

Pronounced "foy-yay", we like to think of ourselves as your gateway to Chinese manufacturing, without all the anxiety and concern in doing business with another country. "Foy-yay," as in the foyer to your house, or the lobby of your business, we are the medium between your delivered OEM parts and your need for Asian pricing. "Foy-yay," as in "yay" for improved costs against the bottom line without the hassle of managing overseas supply efforts, because Foye will do it for you.

Phone

(602) 803-8488

moreinfo@foyesourcing.com

Location

6860 S Yosemite Ct. 2000

Centennial, CO 80112

WHY

-

Foye is an American-owned company, run solely by Americans. Therefore all client IP, NDA's, and PO's reside with Foye and in the United States, and are beholden to its laws and judicial system. In other words, you know where to find us, we are held accountable. That said, to further mitigate IP concerns, our sourcing team will never divulge "all the ingredients of the recipe" to one singular entity in Asia, and therefore there is little to no concern about stolen IP in Asia.

-

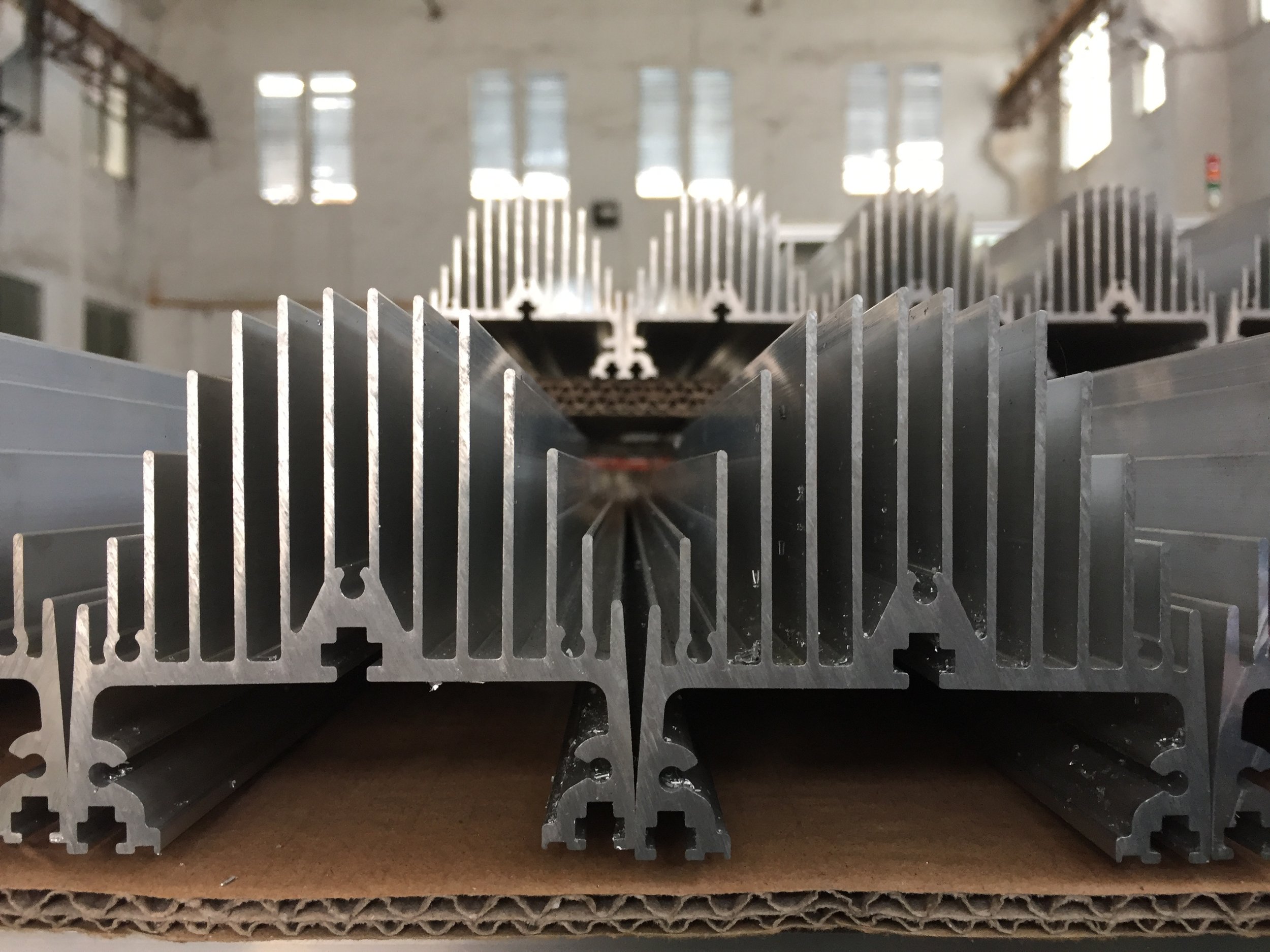

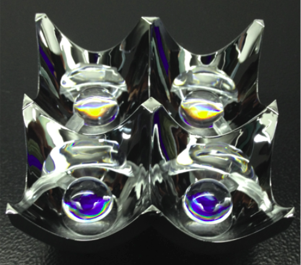

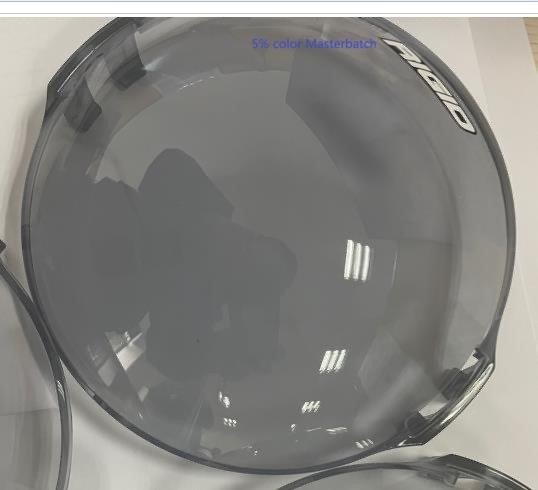

Quality is a fundamental principle of Foye with a top-down approach that ensures quality is considered, planned, and executed at all of our partnered manufacturing sites. Partners are held to industry standard ISO9001 as a minimum requirement with many achieving TS16949 and OHSAS18001 certifications. Best practices utilizing quality control plans, statistical process controls, FMEAs, and SOPs are implemented in every production project. In additions APQP guidelines such as design reviews, limit samples, reliability testing, and even destructive testing (MTBF) are discussed ahead of time with clients to ensure smooth project launches. Our motto is “One hour spent up front saves us 100 hours down the road."

-

With a blanket order, Foye has the financial resources to risk-buy all raw materials, manufacture your goods, and bring them to a warehouse in the USA. From there, we will hold parts until you need them, and deliver in a week's notice, thus reducing your lead time for components to virtually zero. Lately, domestic lead times are a challenge for most OEM's, as the local metal fabricators seem to prioritize automotive and construction contracts. Our standard manufacturing lead time is six weeks, followed by another six weeks for parts to be installed in your local facility or in ours. You can receive parts in 12 weeks, or receive them on a week's notice from our holding area in Denver, CO.

-

With personnel resources in the USA as well as in China and Singapore, speaking both languages natively, Foye offers a seamless medium between the business cultures of USA OEM's and Asian-based manufacturers.

TESTIMONIALS - STORIES OF ADDED VALUE

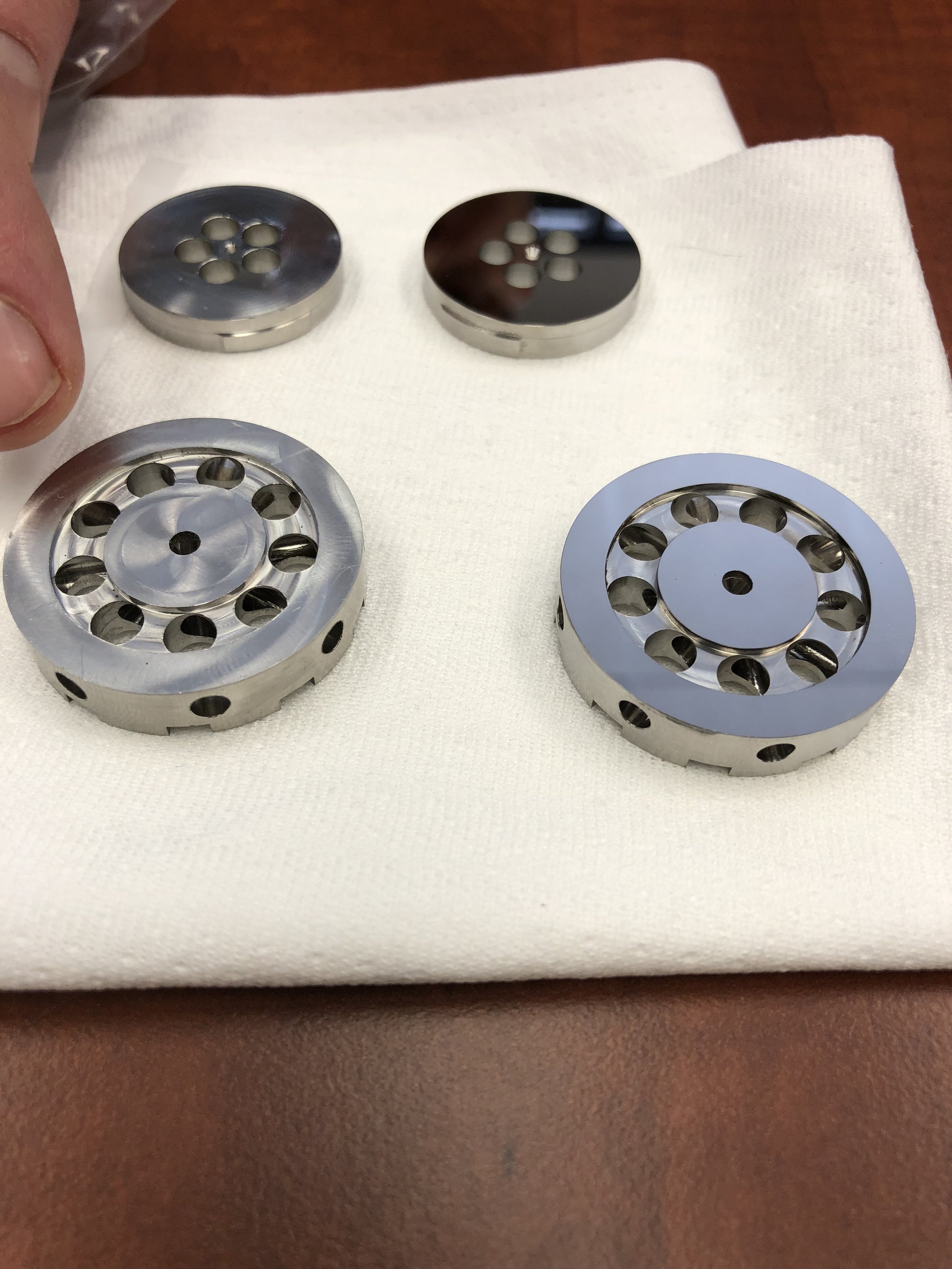

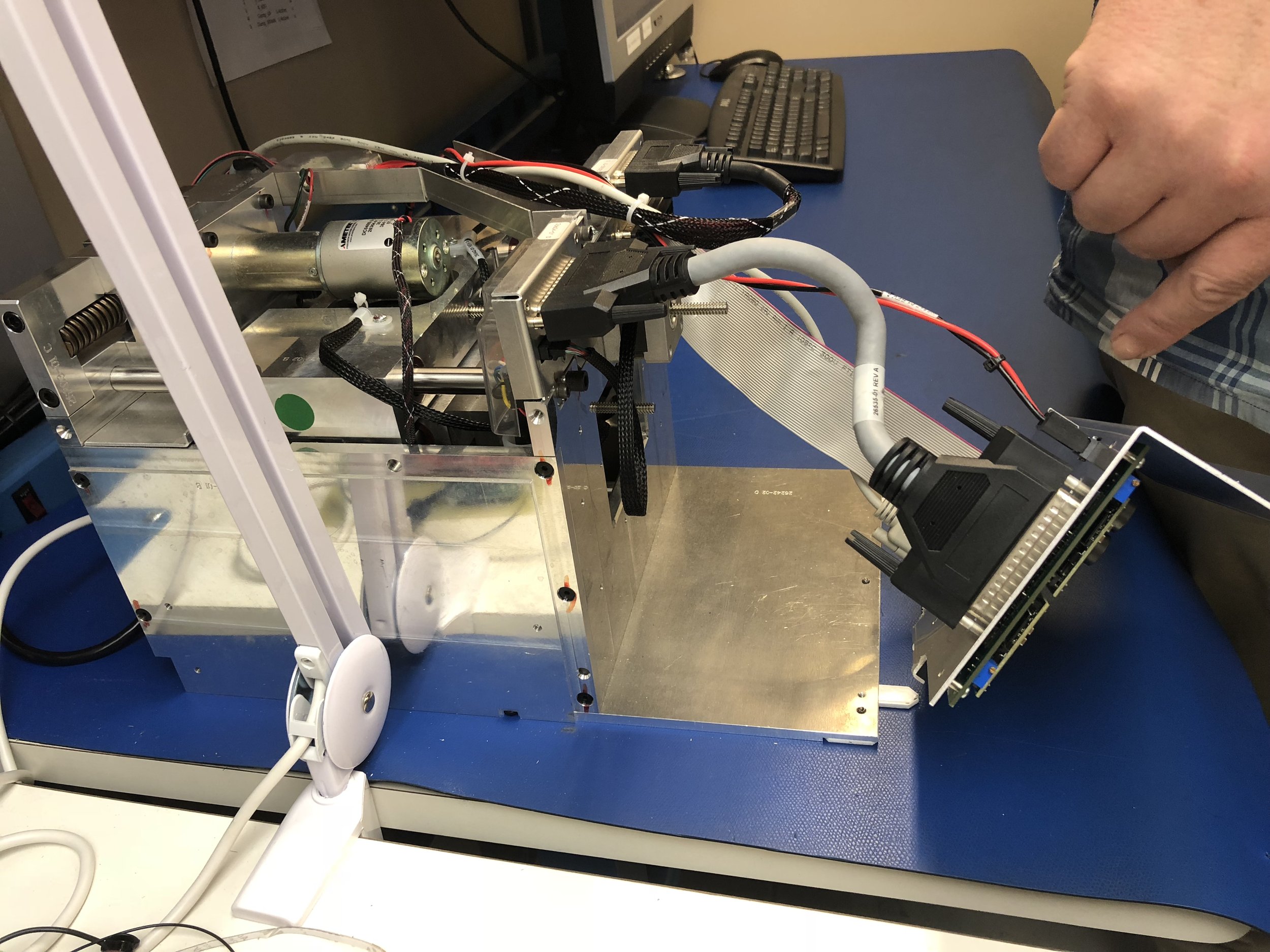

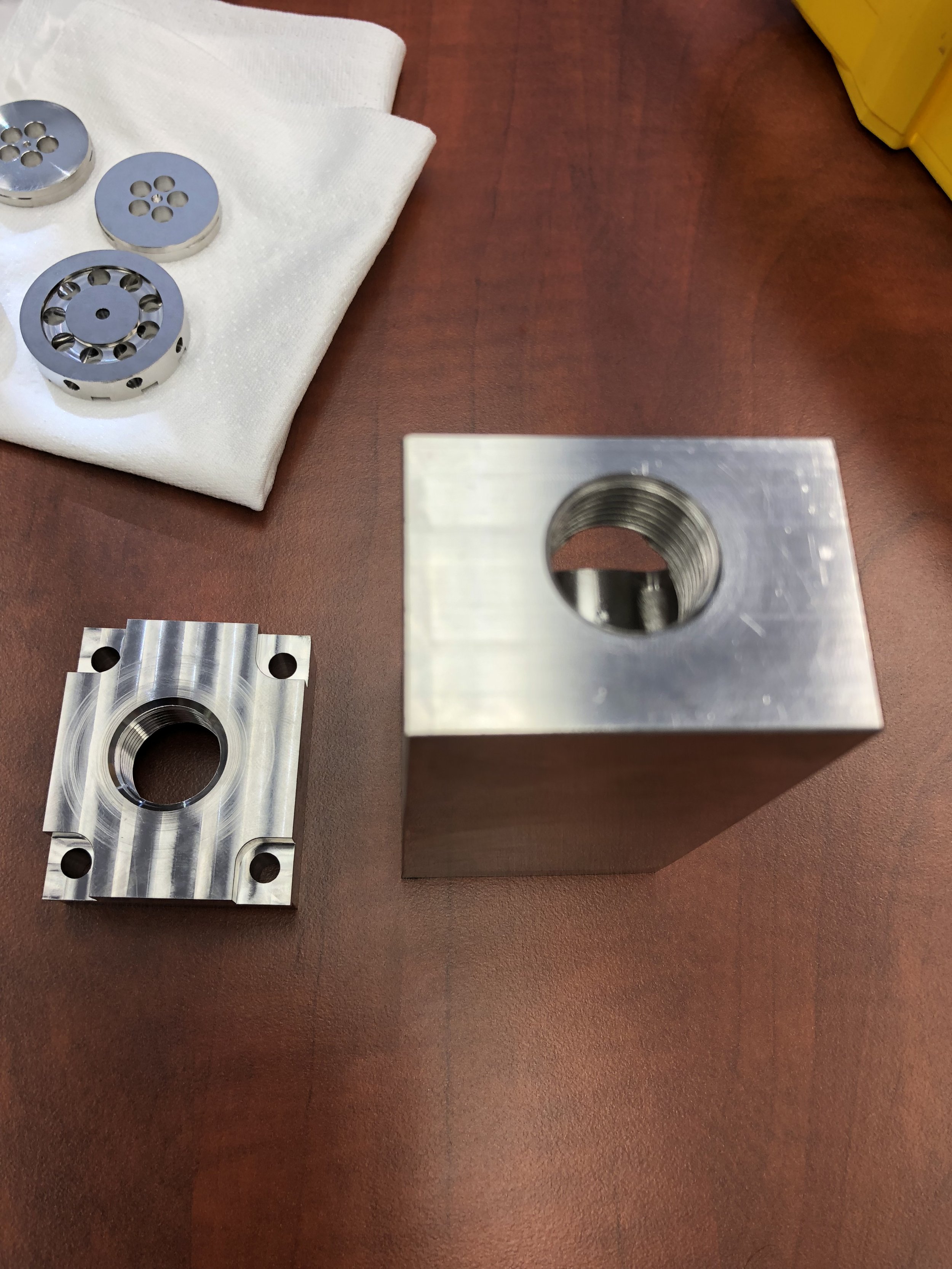

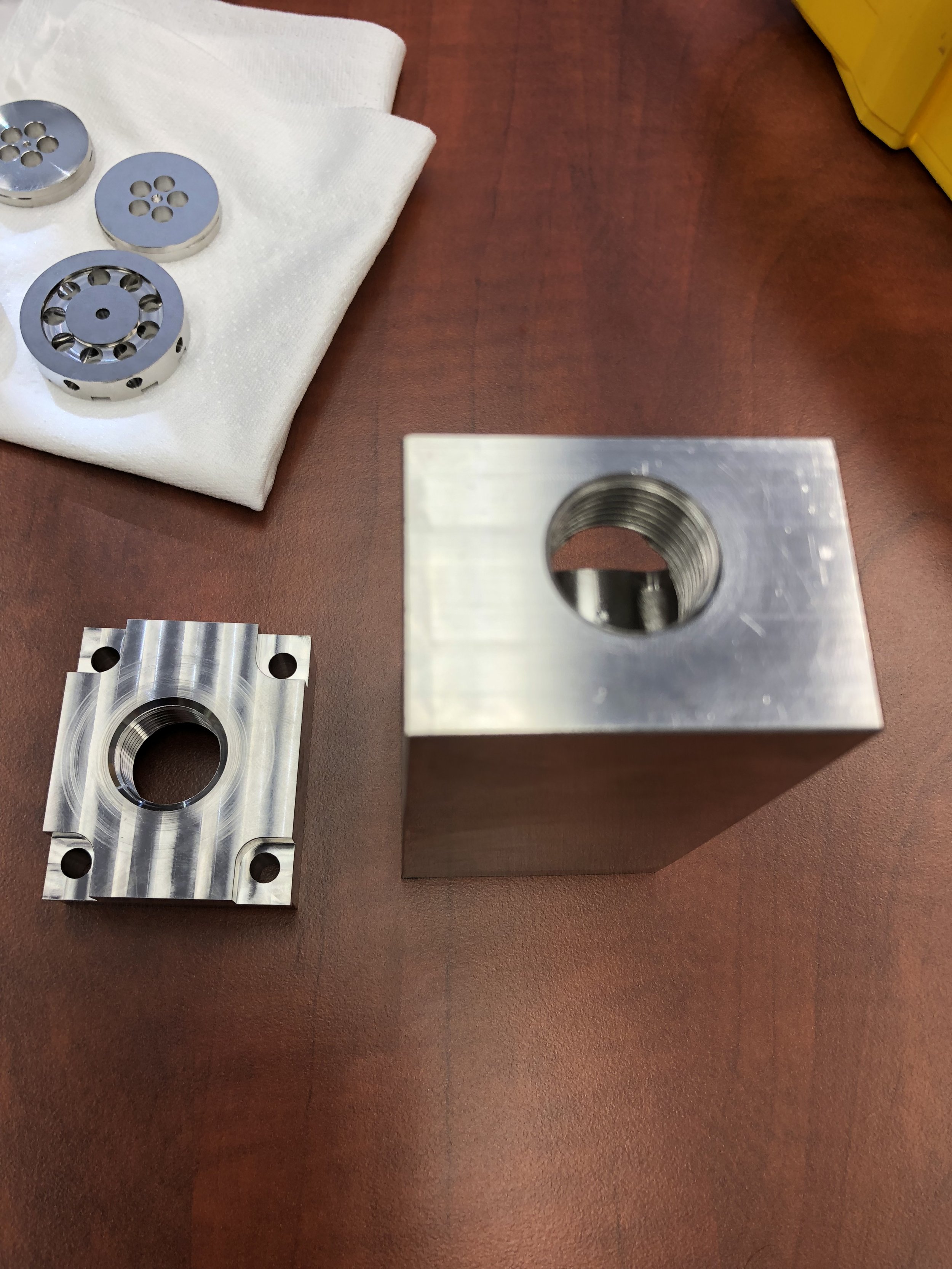

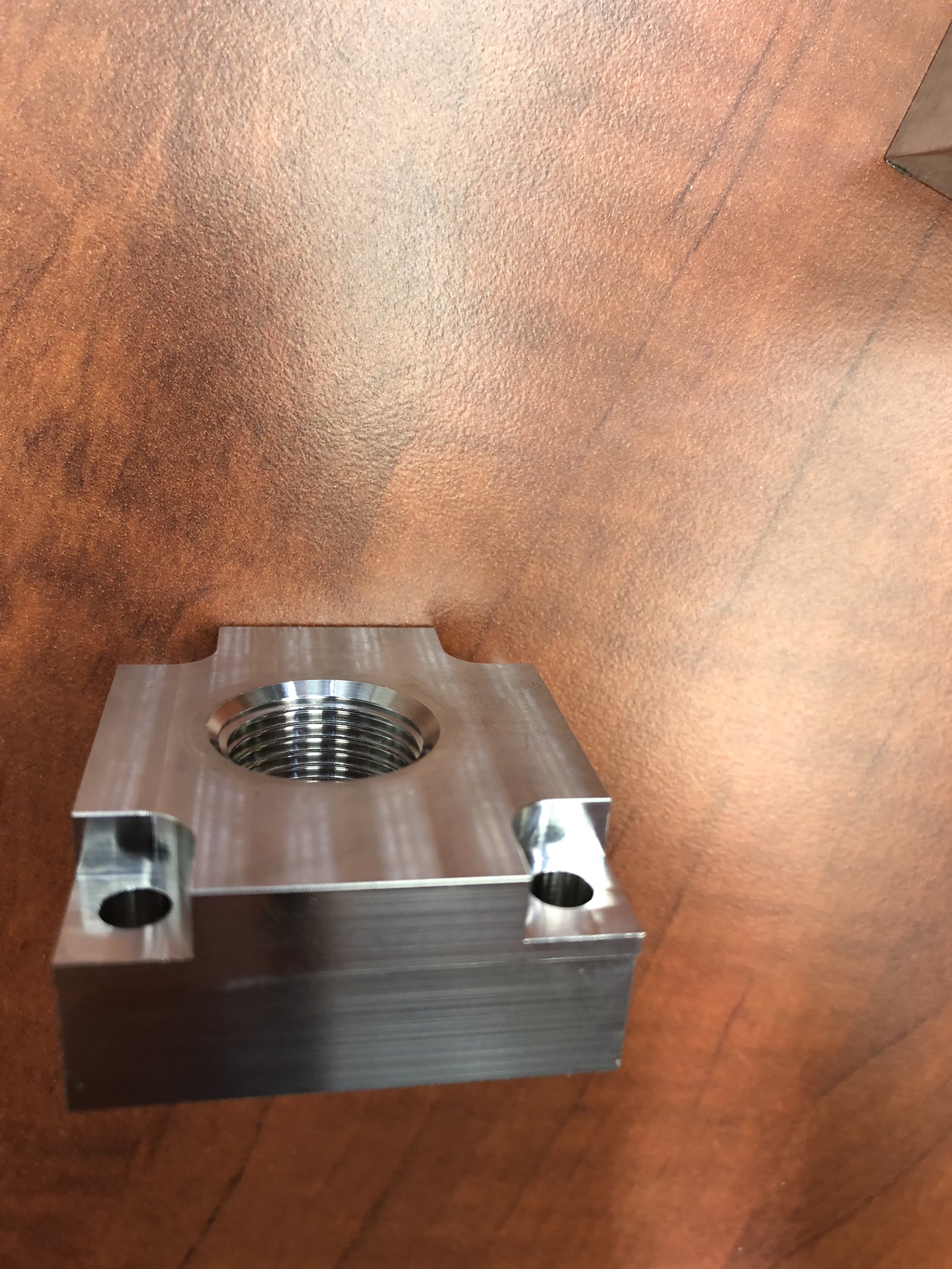

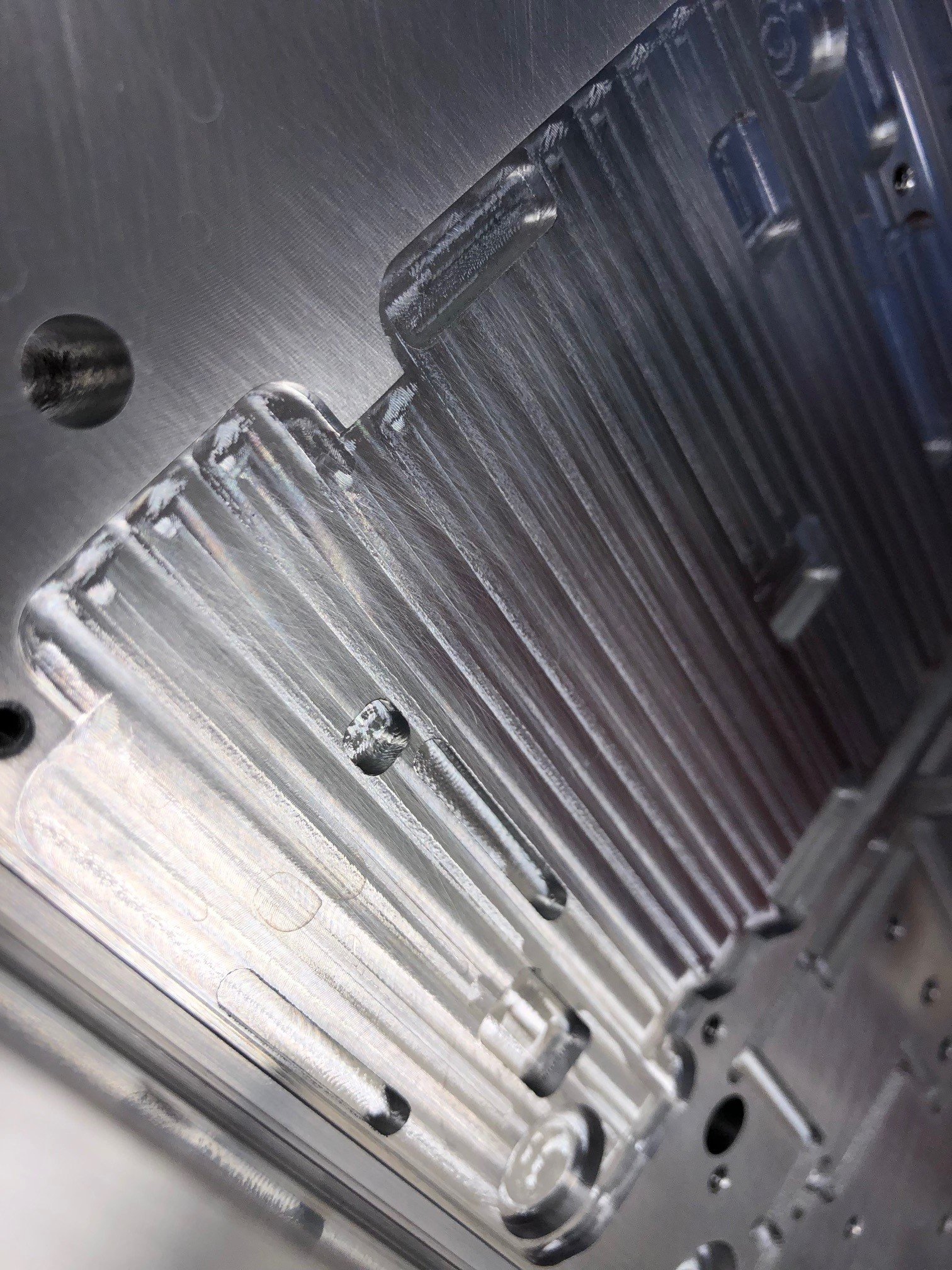

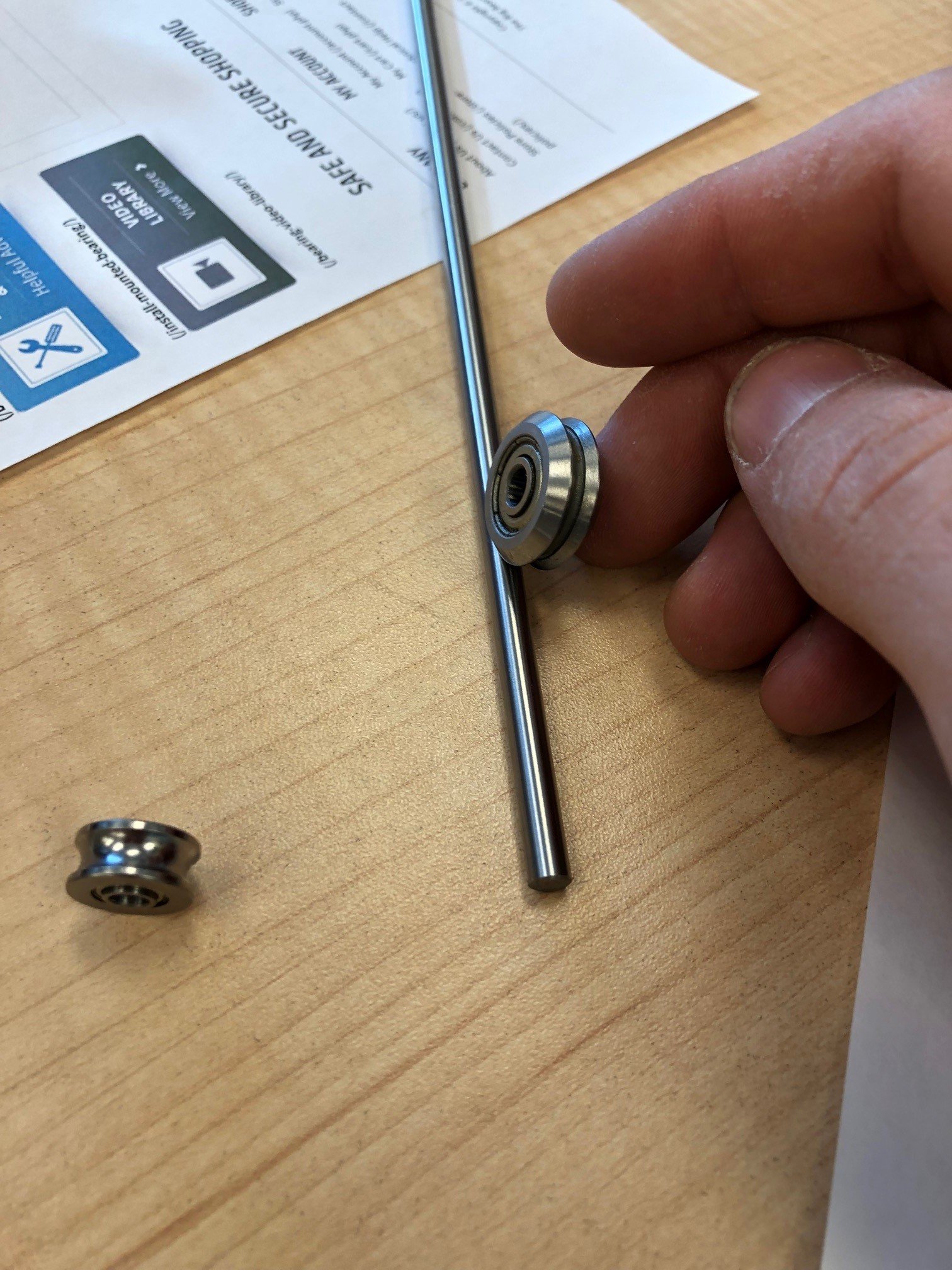

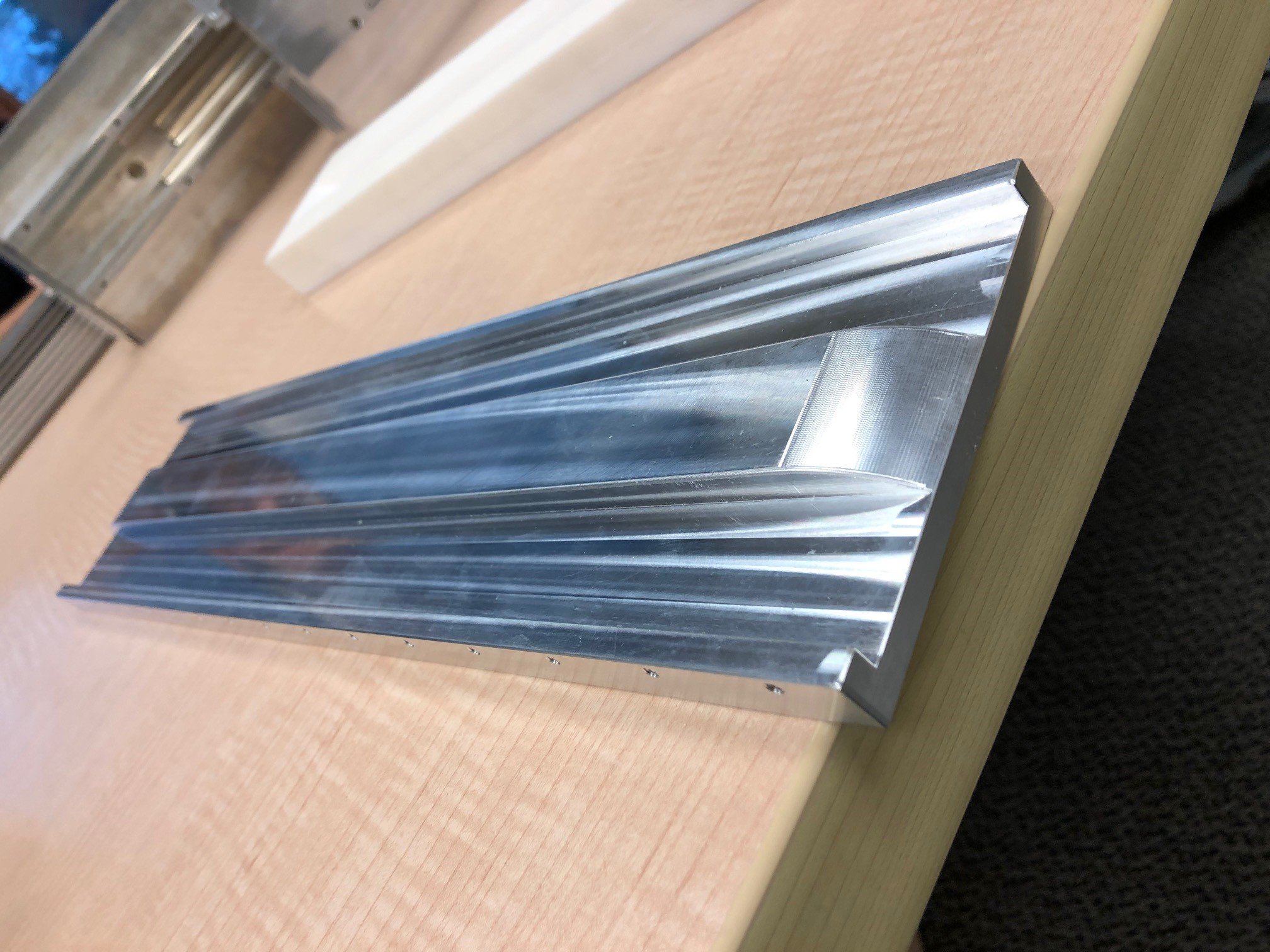

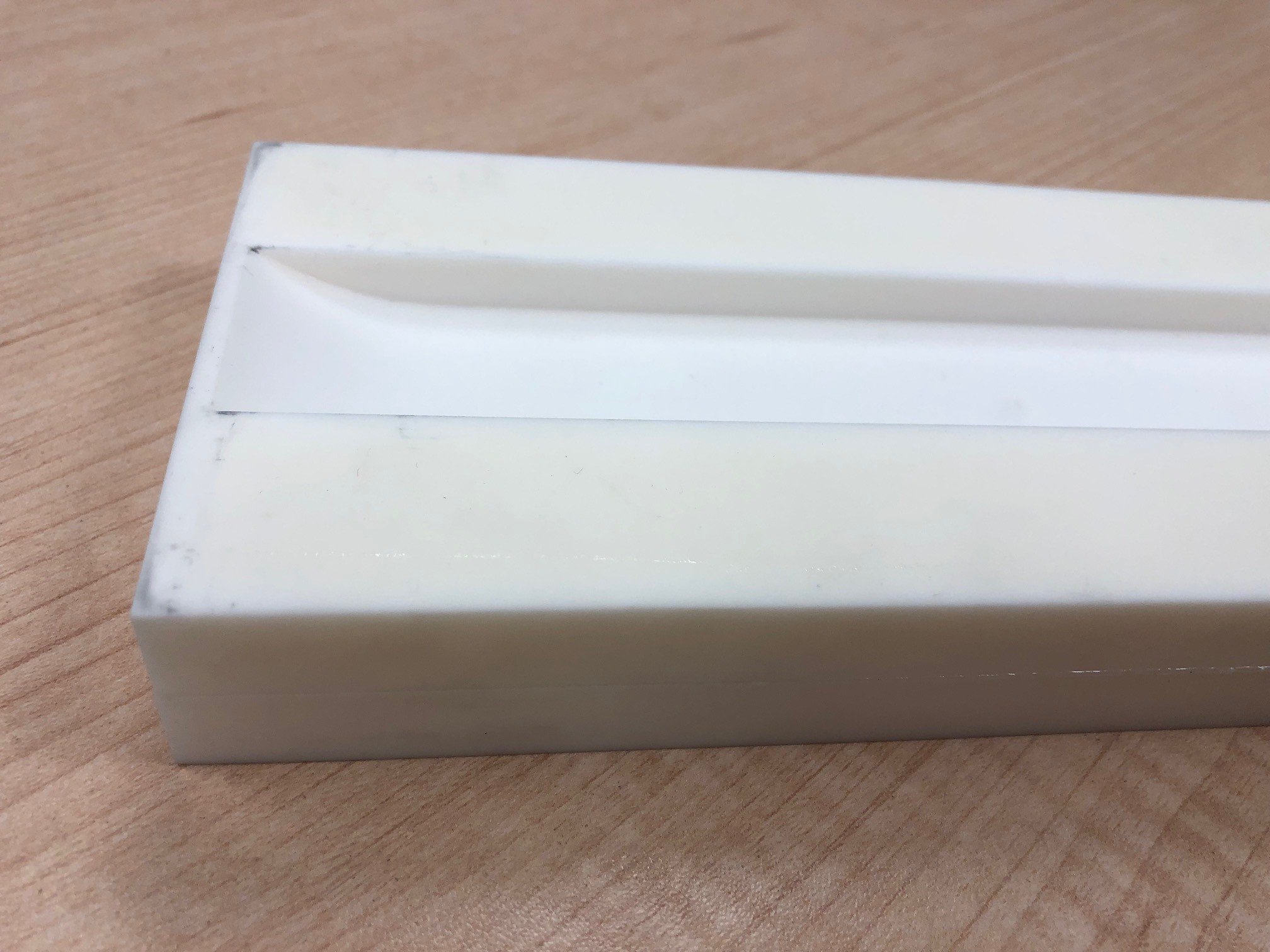

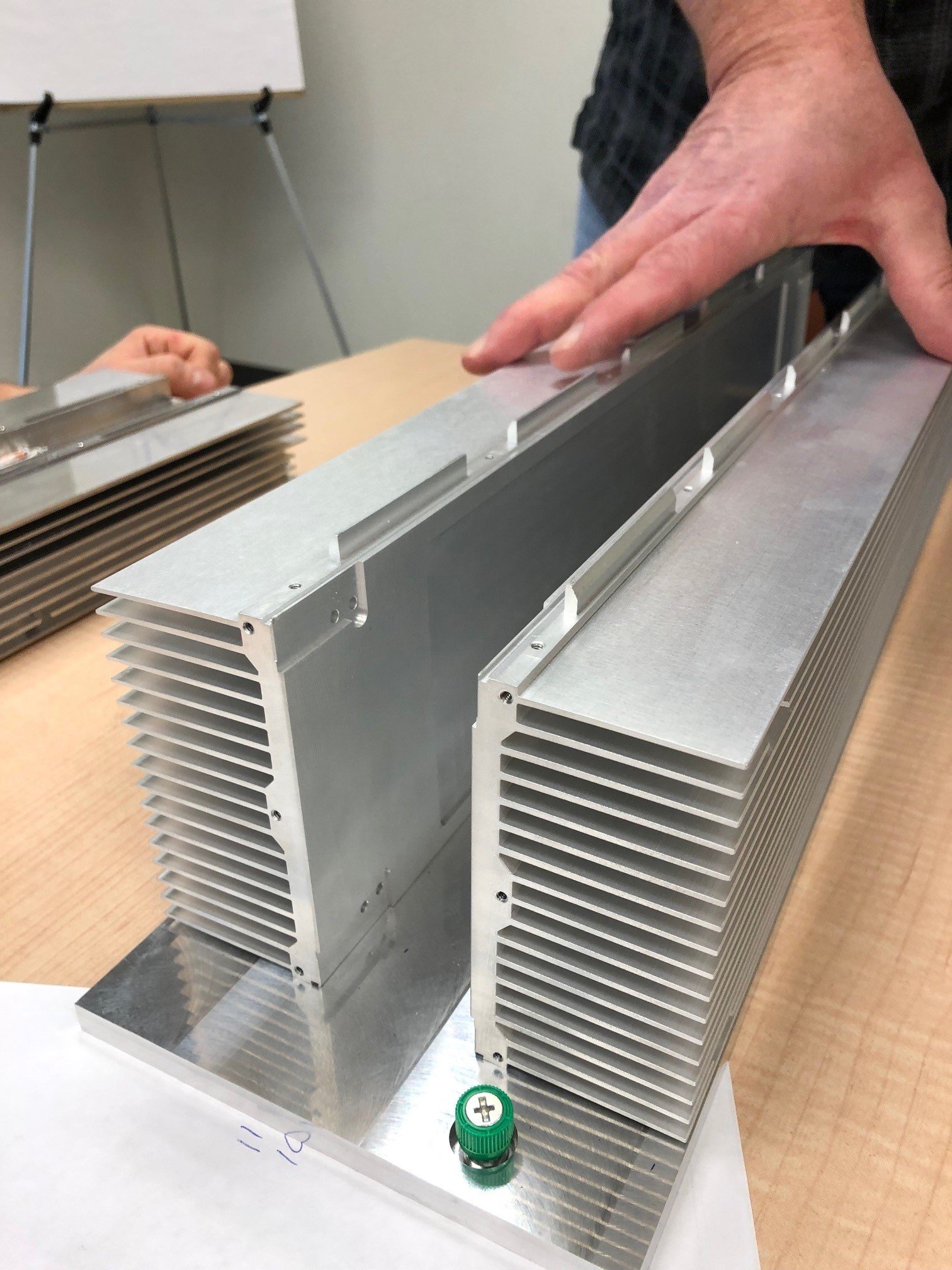

LEAD time - high precision cnc prototyping

Foye was tasked by a client in the oil and gas industry to turn around high precision CNC machined parts in a matter of two weeks, thus arriving to the customer in three weeks time. The parts required a high level of polish to meet a tight flatness spec, which in turn required very specific and unique machining equipment, and the right level of priority and capability to do the job in such a tight time window.

In general, Foye manufacturing lead times are six weeks, but in times of crisis, or in situations requiring expedient prototype samples, we have the right relationships with manufacturers in Asia to have parts made as quick as humanly possible.

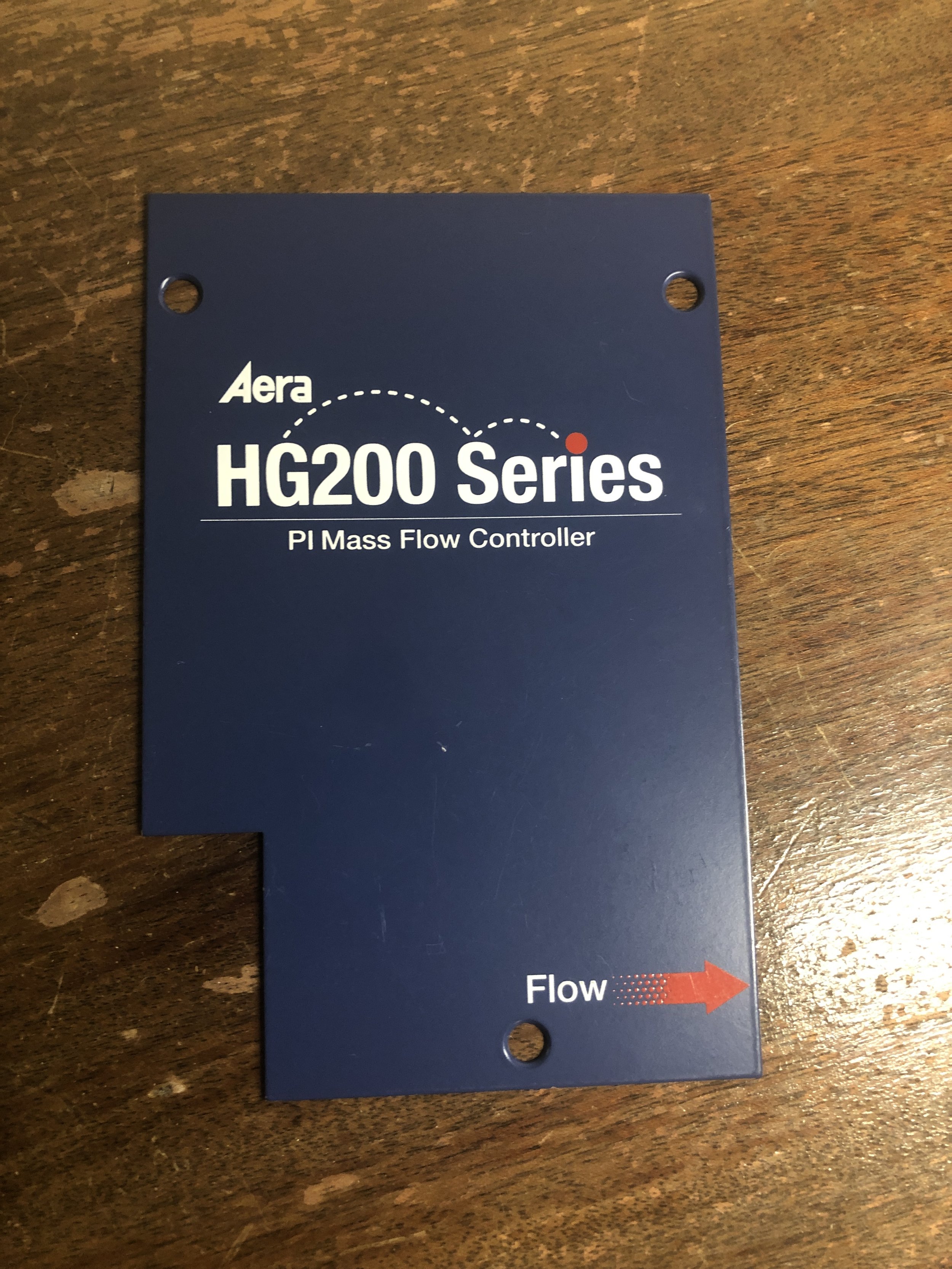

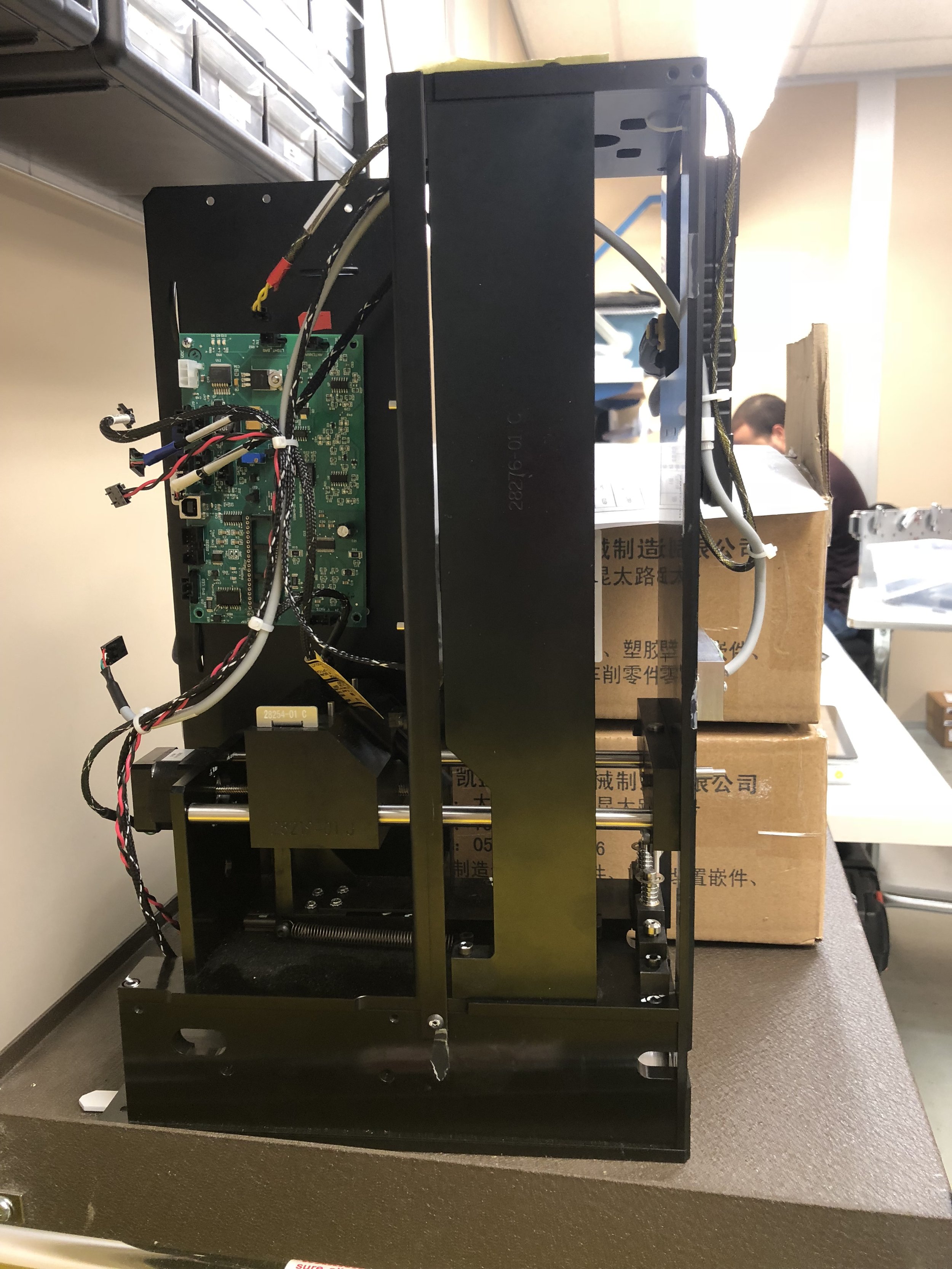

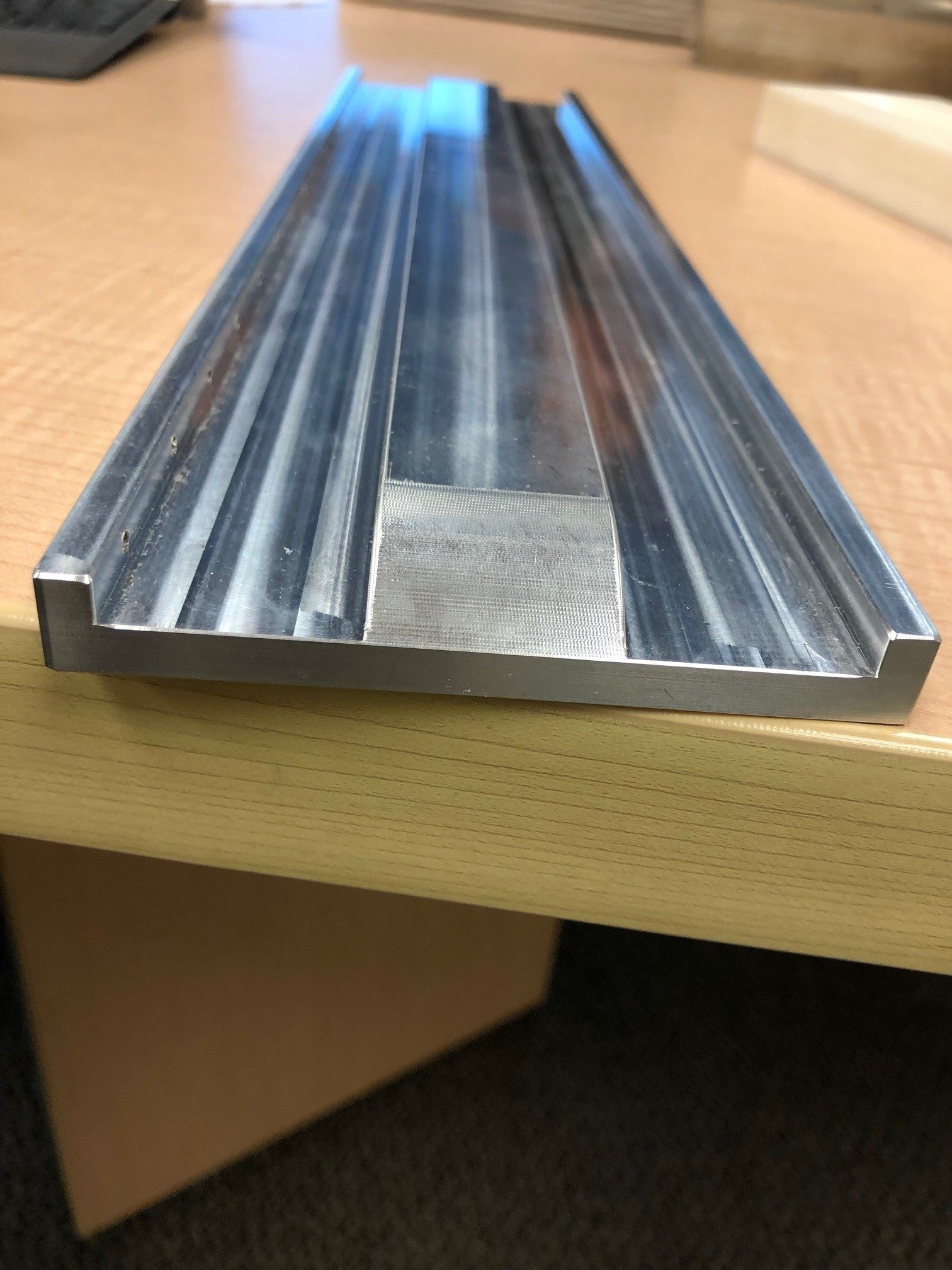

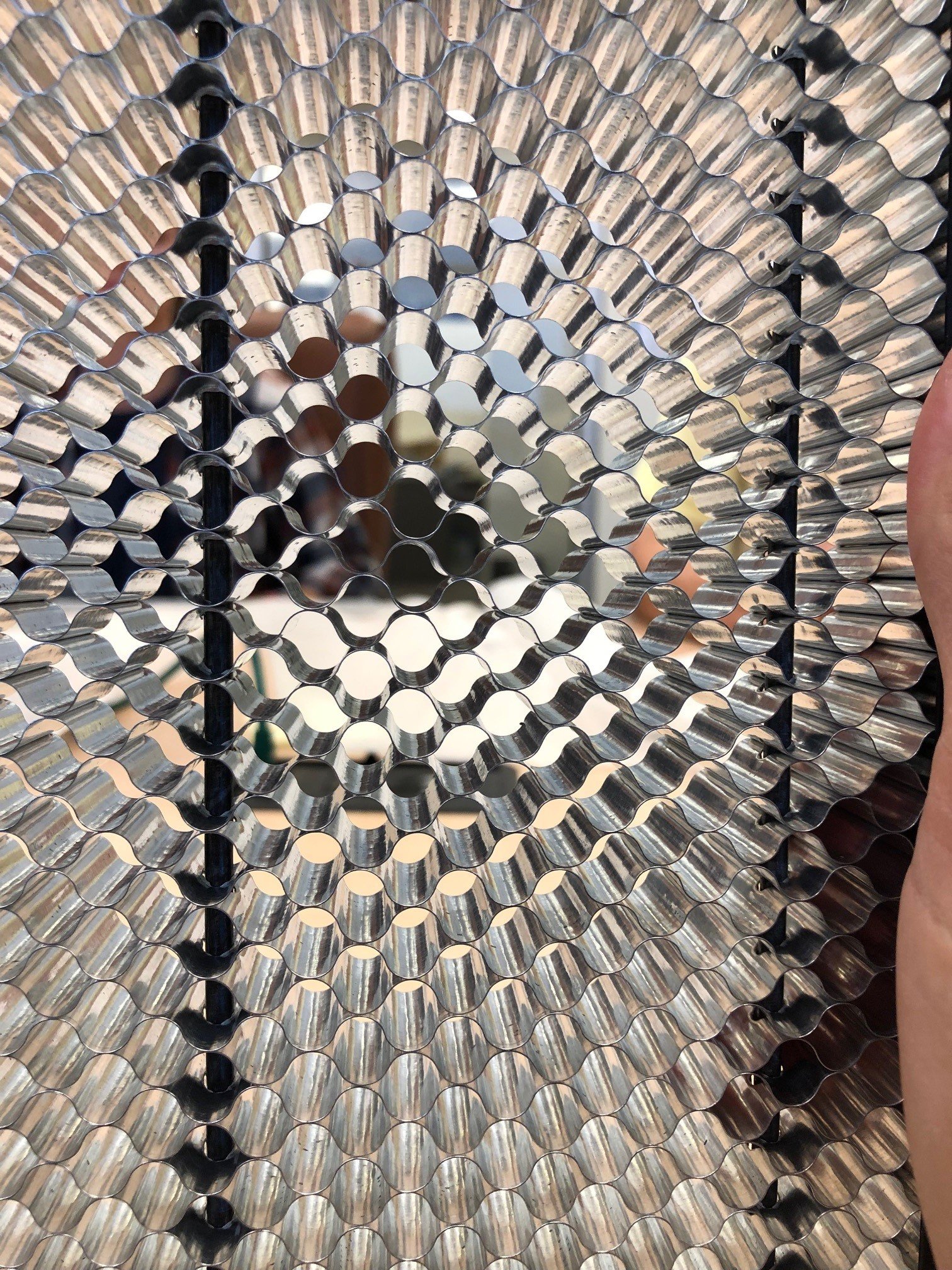

Second sourcing - duplication efforts

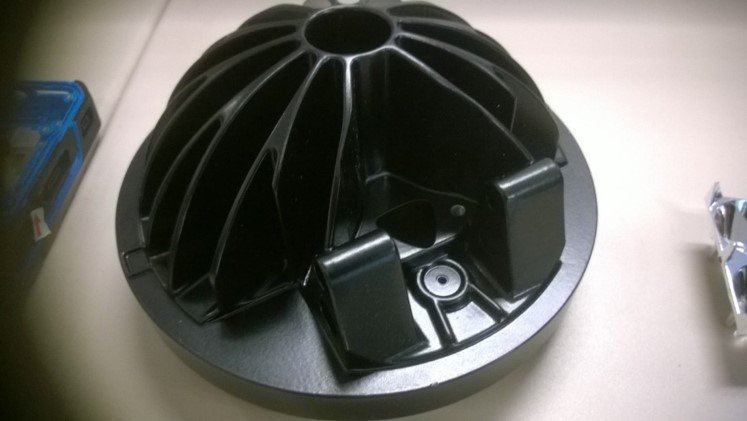

Foye was tasked by a client in the 3D Printing industry to help diversify the metal enclosure business from a domestic fabrication partner. Not only did we save the client money in the end, but we helped to lower their supply chain risk on these critical parts.

The challenge, in this case, was that the client didn’t have a means of differentiating enclosure vendors as orders were fulfilled to end customers, and some customers order multiple printers. Thus, Foye was tasked in a first article process to match silk screen and powder coat paint colors, to the point where the incumbent supplier samples and Foye samples were indistinguishable to the viewer. At that point, Foye was approved as a second source on this commodity.

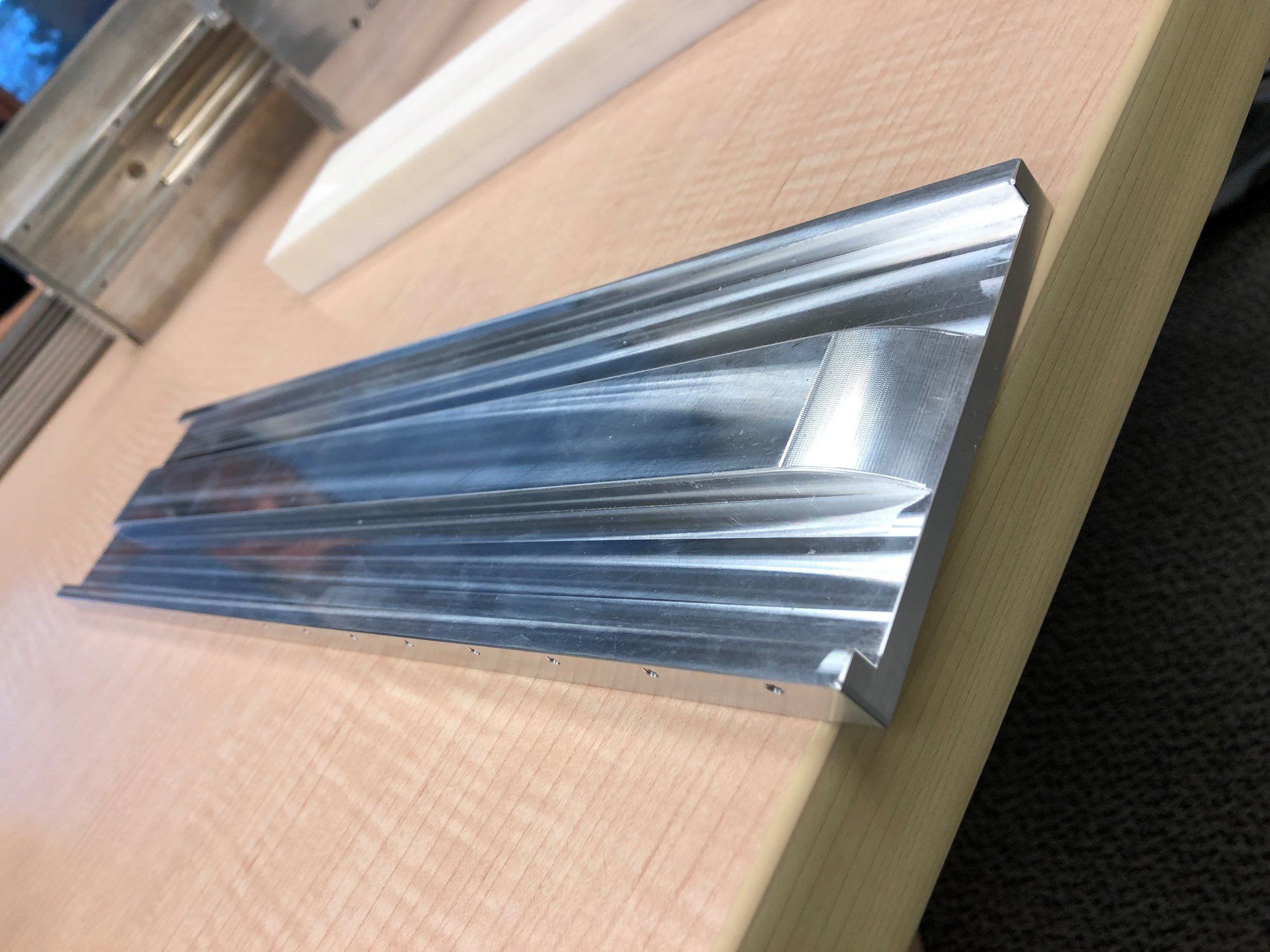

Just In time fulfillment

With responsible cash flow management, and warehousing space in the USA, Foye provides customers with the option to blanket order parts, have them stored domestically, and fulfilled on a week’s notice.

Normally in dealing with Asian manufacturers directly, there are up front payment requirements, where the goods are shipped in bulk directly to destination, and invoiced before the parts arrive for inspection.

With Foye, clients have the satisfaction of knowing they will only be invoiced after parts have been delivered and inspected. This helps clients keep their inventory off the books until the parts are needed. Our warehouse and fulfillment services provide a just-in-time delivery model, to preserve your floor space and your accounting constraints.